Ningbo fenghua hengao machinery co., LTD is located in fenghua

district, ningbo city, zhejiang province, close to ningbo

international airport.The company adopts advanced precision casting

technology, the production of carbon steel, alloy steel, stainless

steel, wear-resistant steel and other material castings, is a

casting scale professional production base, set casting and CNC

machining one.The application of products is very extensive, almost

covering the whole machinery manufacturing and mechanical

processing industry can, application field, mainly mining,

engineering machinery, petroleum, shipping, automobile and other

industries.Can meet domestic and international market demand.The

products are distributed in more than 20 provinces, cities and

regions, and exported to the United States, Italy, Germany, France

and other countries.Our company in line with the "quality first,

reputation first, timely delivery, reasonable price" factory

purpose, with reliable product quality and enthusiastic perfect

service and new and old customers all over the country to

cooperate, establish eternal friendship, create a beautiful

blueprint for development.

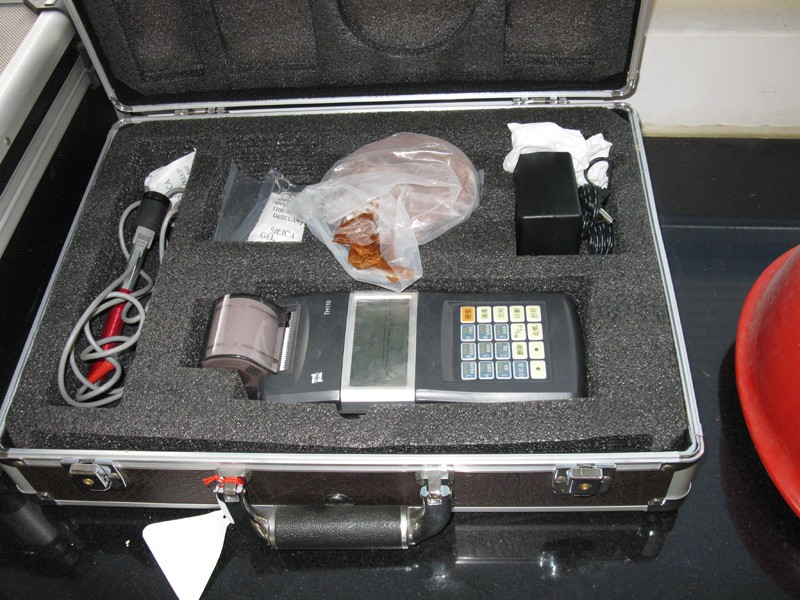

At present, there are more than 120 employees, 15 college graduates

or above, 5 engineers, with an excellent product research and

development team and modern production, testing and testing

equipment.Production base area: more than 6000 square meters, three

intermediate frequency furnace, annual production capacity of more

than 6000 tons.With professional team, strict management and

excellent equipment, we strive to build "hengao" brand.Passion

unrestrained, highlight extraordinary, innovation, enterprising

spirit, inclusive, learn from others, the empty huai na hundred

rivers style.

Company staff adhere to the "quality to win customers, rely on

integrity to seek development, always pursue customer satisfaction"

as the quality policy;"Production qualification rate reaches 90%,

factory qualification rate reaches 100%, customer satisfaction

reaches over 99" as the quality goal, "sincere life, patience,

careful work" as the purpose of the pursuit of win-win, create

"hengao" brand!